Don't see the size you need?

Get a Free quote

We can't wait to hear from you with further details about your perfect Shade Shed. Simply click the button below and fill in our form.

Understanding

CYCLONE RATINGS

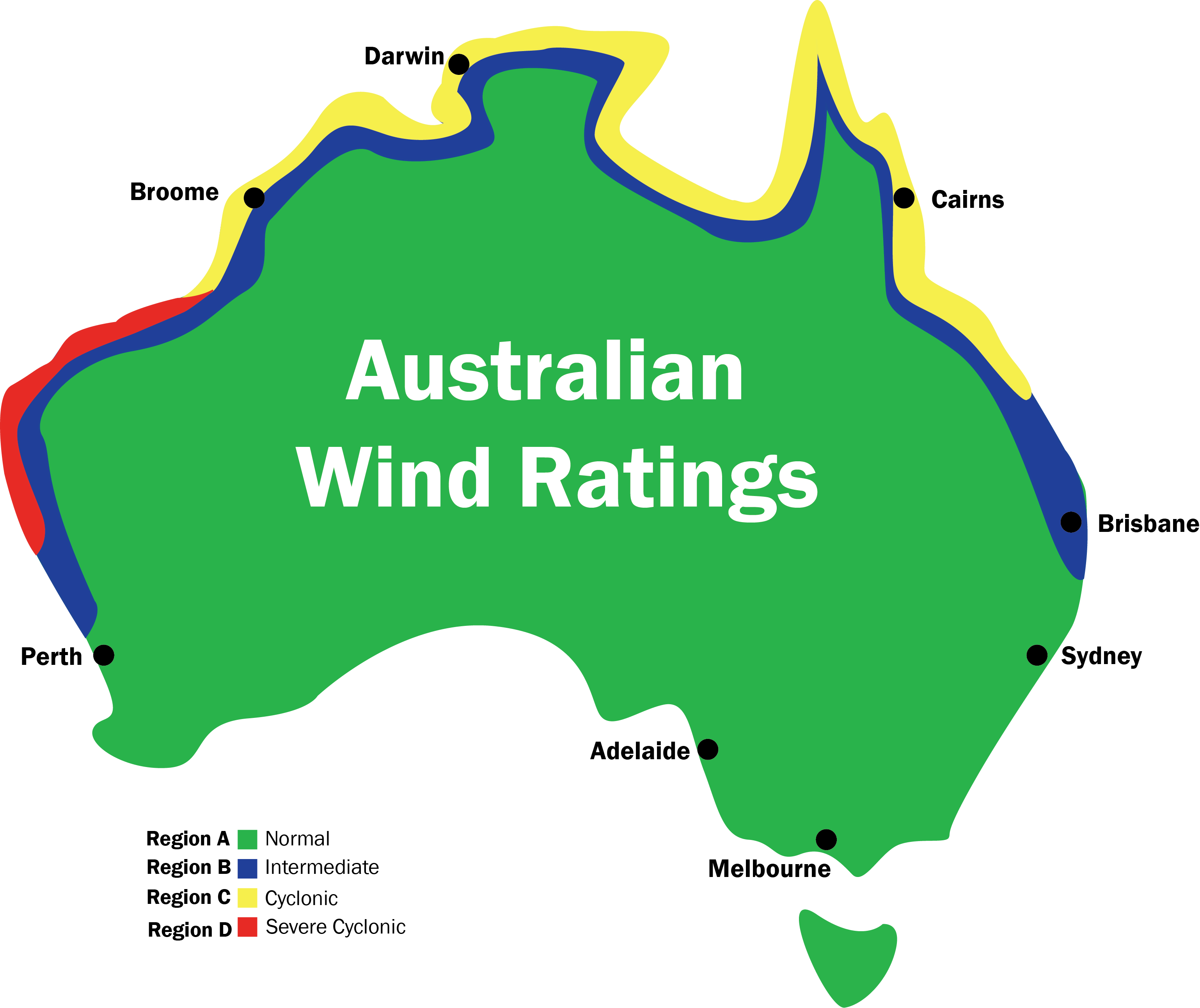

Not sure which wind rating you need? As a general guide, if you're along the QLD coastline from Bundaberg and up into parts of WA, we recommend our C2 (Cyclonic) range.

Our C1 sheds are ideal for non-cyclonic areas with moderate winds (up to 180km/h), while C2 sheds are built for stronger, cyclonic winds (up to 219km/h) with extra reinforcement and cyclone-rated fixings for added protection.

All of our Shade Sheds are available in both C1 and C2 to suit your location (Please Note: Quickshades and Canvacons are not cyclone rated).

Check your requirements

Do I need a Cyclone Rated Shade Shed?

If you live in Northern Australia, coastal regions, or high-wind areas, you may need a C2 shed. Check your local council regulations as some areas require cyclone-rated structures for compliance.

Every shade shed is designed and certified for C1 and C2 wind-rated areas. We offer four different hold down options to suit a variety of ground conditions—whether it's a concrete slab, bare earth, or a semi-permanent solution. Not sure? Our team can guide you based on your location and intended use.

DIY INSTALLATION

DIY Install

Our shade sheds are supplied as pre-engineered, easy-to-assemble kits designed for straightforward DIY installation. Each kit arrives with all required components and clear instructions, allowing customers to install their shed without specialised tools or the need for a concrete slab.

Optional anchoring systems are available for added stability depending on site conditions. Thanks to our slip-fit (swaged) design, assembly is quick, simple, and secure.

Tools Required

- Impact driver

- Tape measure

- Level or string line

- Sledgehammer (if using Ground Anchors)

- Tin snips (for flashing)

Tip: Lay out all parts first and check your site is reasonably level before starting.

Base Rails & Portal Frames

1) Build the Base Rails (Slip-Fit)

Shed construction starts at the base rails. Some rails have swaged (reduced) ends that slip inside the next rail — this is our slip-fit system.

Slide each swaged end into the next rail and ensure everything is aligned. Secure every slip-fit connection with screws on both sides before moving to the next rail.

2) Grounding (If Selected)

If you’ve chosen a grounding option, place anchors beside the base rail between portal positions, mark the locations, then move the rail aside and drive the anchors into the ground.

Reposition the base rail over the anchors and fasten the saddle brackets down to secure the rail.

3) Assemble Portal Frames

Assemble each portal frame by slipping the swaged ends together. Depending on your shed design, this may include pitched pillars, apex, risers, and rafters.

Check your frame is square by measuring across the top and bottom. Secure each connection with screws on both sides.

Riser Kit & Rafters

1) Optional Riser Kit

When building on uneven ground, the optional riser kit helps level the shed. Run a string line across the base rails and adjust the risers until the string sits level.

Measure from the string line down to the base rail to confirm the correct rise needed.

2) Square Up & Install Portals

Install the front and rear portal frames first. Adjust the base rails so the top and bottom widths match, then take diagonal measurements.

When both diagonal measurements are equal, the shed is square. Install the remaining portal frames and use a string line along the top to ensure consistent height.

3) Rafters (If Included)

If your shed includes rafters, install them between the apex and pillars. Once aligned, secure all connections with screws.

Roofing & Flashing

1) Align the First Roof Sheet

Place the first sheet on the frame and align it so it sits straight and centred. Mark screw positions at the front, middle and rear portal frames.

2) Fix Sheets & Overlaps

Screw the first sheet to all portals. Slide the next sheet under the previous one, screw the overlap, then fasten it to the frame.

3) Flashing (If Selected)

Cut small relief cuts (~10mm) so the flashing bends cleanly. Attach from one corner and work your way around the shed.